Material Properties of High-Performance Cookware

What makes 'high-performance cookware'? From a technical perspective, it comes down to two things: the materials used and the way those materials are combined.

Words:

Kate Swanson

Photography:

Nathan Lang

Artwork:

Tiffany Chan

Part One:

The Materials

High performance cookware is made from materials that combine high thermal diffusivity and low reactivity to produce a vessel that evenly distributes heat and does not react with the food being cooked.

Thermal Diffusivity

Cookware needs to evenly smooth out the uneven heat received from the stove’s element so there is a consistent temperature across the surface of the pan. Uneven heat will lead to hot spots across the pan, meaning some food will overcook or burn while some food will remain undercooked.

Cookware therefore needs to:

- React quickly to changes in the energy it receives (the heat), and

- Quickly transmit the energy (the heat) it receives across the pan.

A material’s ability to react to and transmit energy is called thermal diffusivity. Materials with high thermal diffusivity react quickly to energy received and quickly transmit the energy received while materials with low thermal diffusivity react slowly to energy received and slowly transmit the energy received. Copper and aluminum are considered to have high thermal diffusivity while stainless steel is considered to have low thermal diffusivity.

Example

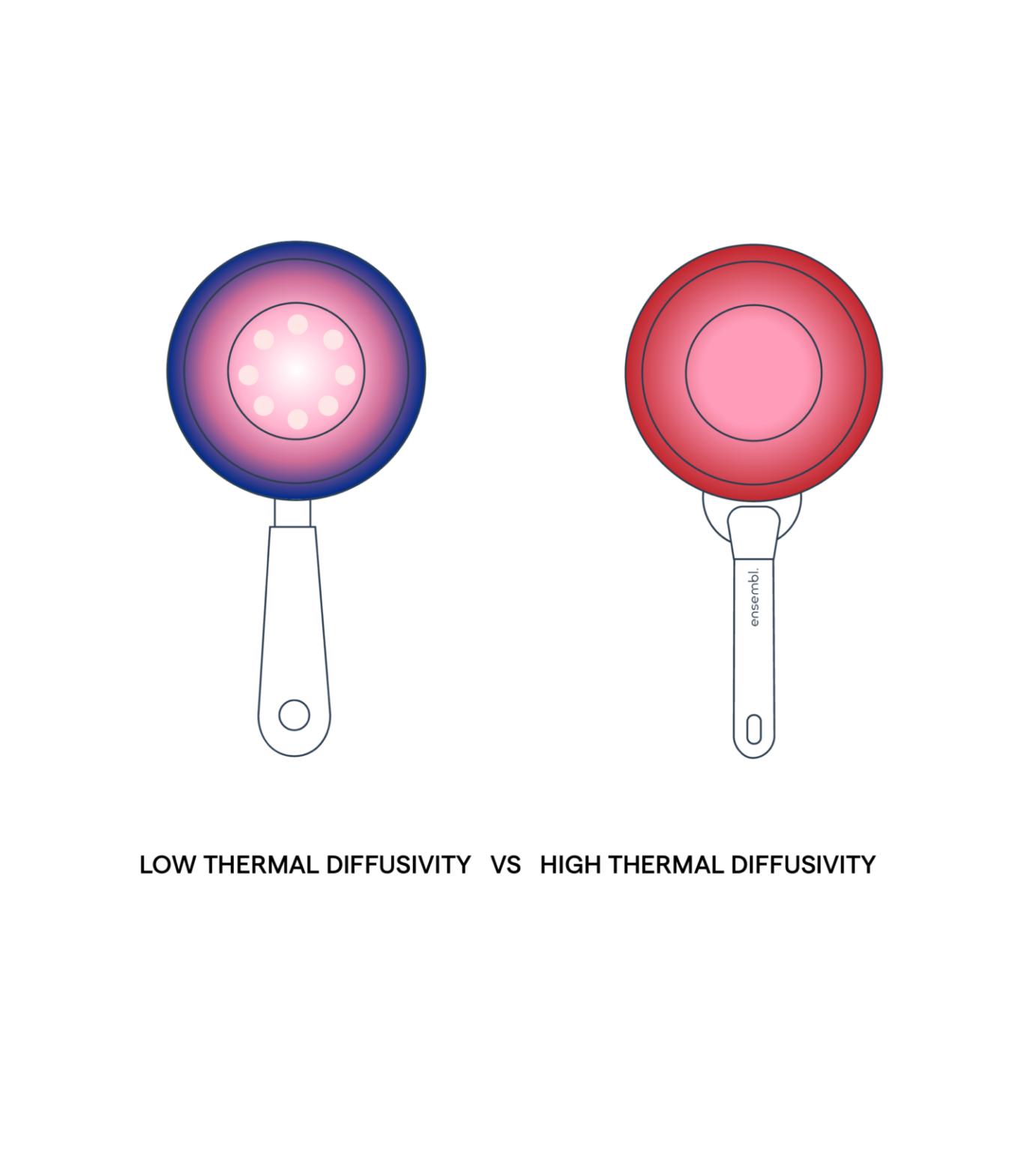

Low thermal diffusivity. When a cooking vessel is placed on a hot element, the area directly over the element will get really hot. The element, however, only imparts heat to the parts of the vessel which are in contact with it. The rest will only heat up as the energy is transmitted throughout.

If the vessel is made of materials with low thermal diffusivity, it will take a long time for the heat to transfer. While the vessel heats across, the burner on the stove will continue to transfer more heat to the area directly above it. This means that by the time the outer edges of the vessel are “hot”, the spot directly over the burner will be “extremely hot”. The “extremely hot” parts of the vessel are referred to as “hot spots”.

High thermal diffusivity. When a cooking vessel is placed on a hot element, the area of the pan directly under the element will heat up quickly and begin to transmit heat. Because of the speed at which the heat is transmitted, the vessel will have an even distribution of heat across the cooking surface.

Grilled cheese does a great job of showing the difference between cooking on a pan with high thermal diffusivity versus a pan with low thermal diffusivity.

- Low: cooks quickly in the middle but slowly around the edges. By the time the outer cheese has melted and the edges of the bread have browned, it’s likely that the middle, especially where the “hot spots” are located, will be burnt.

- High: browns evenly, and the cheese will melt uniformly.

Reactivity

Great cookware also needs to be non-reactive, meaning the metal should not react with the food being cooked. If the material the cookware is made from reacts with the food in the pan, the taste of food can change, and chemical elements from the material may leach into the food.

Highly reactive metals include copper and aluminum. Non-reactive metals include stainless steel.

How To Get The Benefits Of Both

In order to get the benefits of high thermal diffusivity materials (like copper or aluminum) plus the benefits of non-reactive materials like stainless steel, cookware should be made with layers (each layer is called a ply).

Cookware can be engineered so that it has stainless steel on the surfaces that comes in contact with food, with one or more materials with high thermal diffusivity, like copper or aluminum, in the middle. In this way. the food never comes in contact with reactive materials, but the cookware has the benefit of even heat distribution across the surface.

The Optimal Combination Of Materials

Based on the information outlined above, it can be established that a single material cannot provide everything to a user. Materials with high thermal diffusivity are reactive with foods, while materials that won’t react with foods have low thermal diffusivity. The material’s propensity to rust or tarnish and its ease of use and cleaning must also be considered.

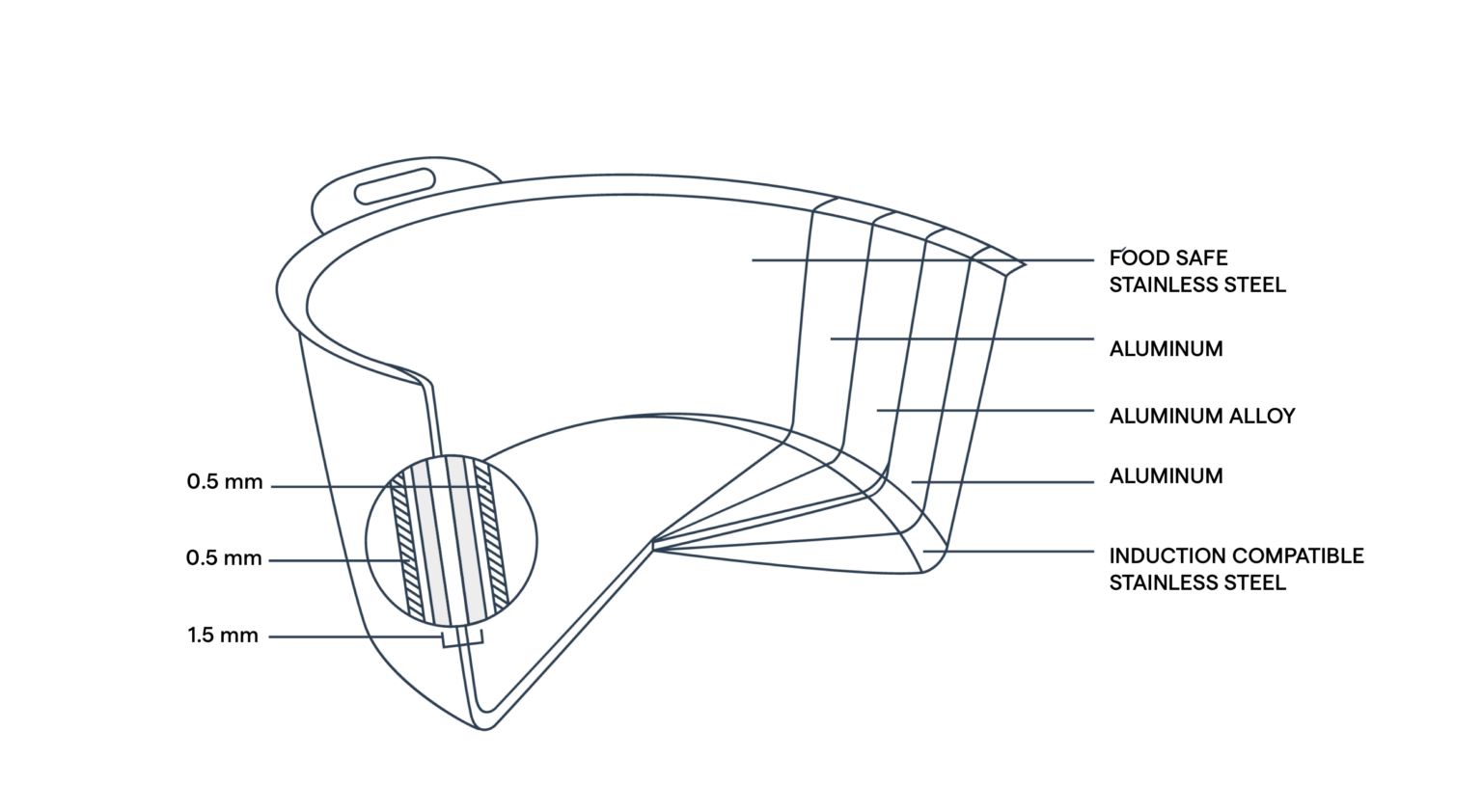

The solution is to combine multiple layers of materials: non-reactive, durable materials for the shell of a pot or pan to ensure nothing is leached into your food and the cookware will last, and materials with high thermal diffusivity at the core to ensure the cooking vessel will be able to absorb and transmit heat evenly throughout.

Stainless steel is a great option for the inner and outer layers of a cooking vessel– it does not react with food, is not prone to rust or tarnish, and can be magnetized, meaning it can be used on an induction cooktop. To make a cooking vessel that’s easy to maintain and works on all cooktops, stainless steel is a fantastic choice for the pot’s shell.

Between the layers of stainless steel is where we want to use materials with high thermal diffusivity – this is what will ensure the vessel absorbs and transmits heat evenly across the cooking surface.

It is important to note that thermal diffusivity changes by material and increases by thickness, so in order to determine how evenly a pot will heat you need to consider both the type of material and its thickness.

Both copper and aluminum have relatively high thermal diffusivity compared to other metals; note that we can achieve similar results by using about 0.5mm of copper or 1mm – 1.5mm of aluminum.

How To Shop For The Optimal Combination Of Materials

It is important to call out that cookware is not typically sold based on thickness of a particular material. Instead, it is sold based the number of plies (layers).

This can be confusing because the thickness of a ply is not standardized and does not differentiate between materials. This means that:

- the number of plies is not indicative of thickness (five layers that are 0.5mm thick is not as thick as three layers that are 1.2mm thick),

- the impact of thickness will depend on the material used (recall from above, 0.5 mm of copper should produce results similar to 1mm – 1.5mm of aluminum.

Therefore, the actual thermal diffusivity will be based on the material used AND its thickness.

What to make of this?

Multiple layers are important, but getting caught up in the specific number of plies is not. (Take a minute to let this sink in, as this is NOT how cookware is currently sold.)

What we want is multi-ply cookware: a thin ply of stainless steel on the outside and inside of the cooking vessel the interior is non-reactive while the exterior is durable, and a thicker ply of copper or aluminum on in the middle so the heat is evenly distributed across the cooking surface.

If using aluminum, a thicker layer is required in order to achieve a similar thermal diffusivity as copper.

Part Two:

Combining Materials

How do the multi-layers come together?

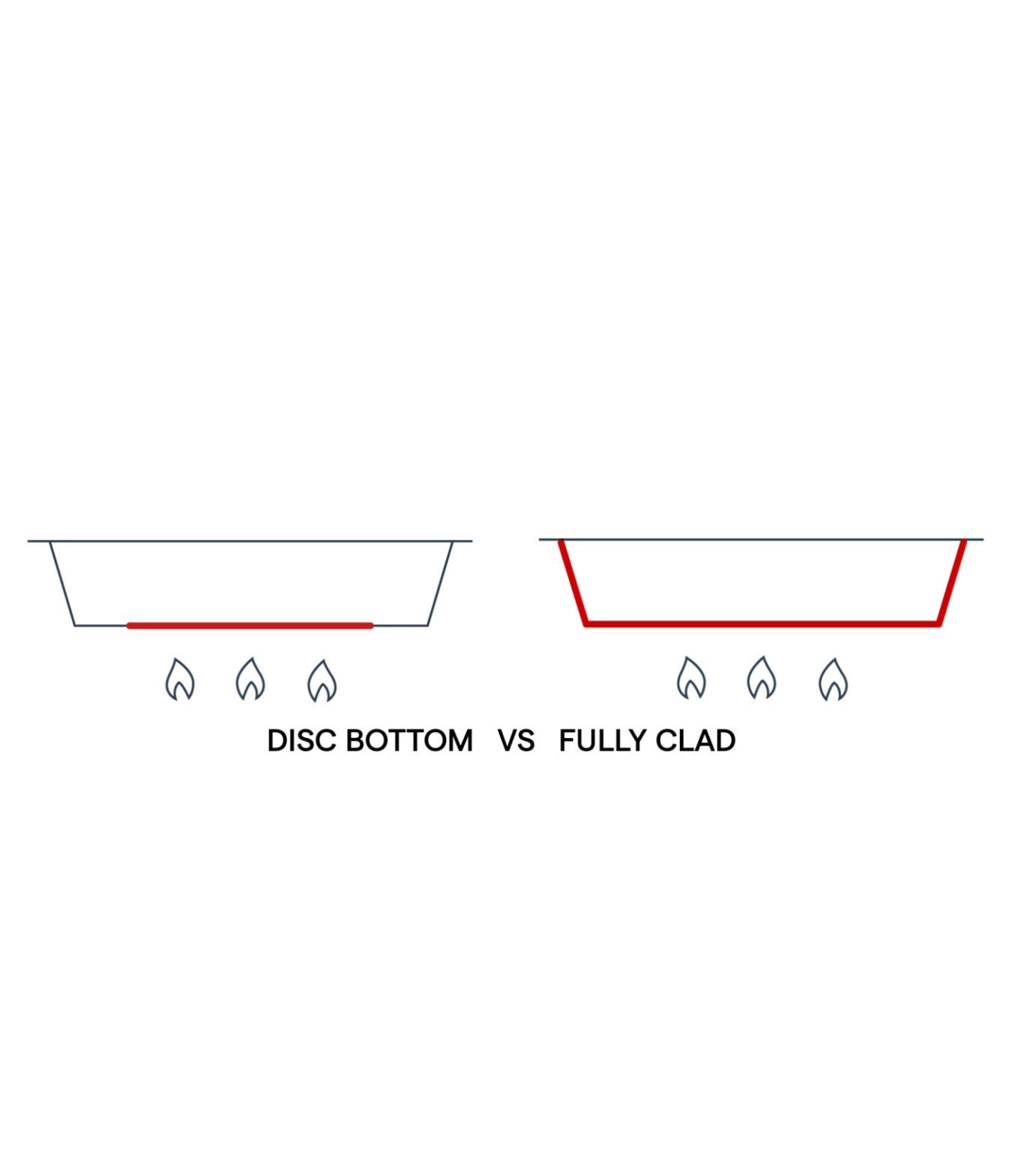

There are two options: a multi-ply layer can be added to the base only while a single layer of stainless steel is used for the sides (disc bottom) or the entire vessel can be made from a single, uniform sheet that combines all the metals and is multi-ply throughout (fully clad).

It is less costly to create a vessel with a disc bottom than a fully clad pot vessel (less copper or aluminum is used, both of which are more expensive than stainless steel), the benefits of using a fully clad pot are well worth the premium. Here’s why:

Disc bottom pots suffer from thermal discontinuity, which means the heat will be different depending on where you are in the pan. This is because the heat will be transferred quickly across the disc bottom compared to slowly across the sides.

The bottom of a disc bottom vessel is likely to overheat while the top and sides remain cool. As a result, total surface area with even heat is reduced, being limited to the bottom central area of the vessel.

This can be an issue when making dishes where the full surface of a cooking vessel is required, such as a stir fry, curry or tomato sauce. Disc bottom pots also run the risk of burning and scorching food at the outer edges, especially when cooking on a gas stove, as the gas pushes out to the edges and is prone to overheating certain areas.

In contrast, fully clad cookware evenly distributes heat across the entire cooking vessel – both the bottom and sides – providing an even, large cooking surface. Burning or scorching food is also less likely than with a disc bottom pot as there won’t be major temperature changes where the materials change (since there are no material changes!), and cleaning should be easier as there won’t see unexpected scorch marks.

The bottom line

High-performance cookware is going to be multi-ply and fully clad, made from a stainless steel shell and a core of either copper or aluminum.

If using aluminum, note that a thicker layer is needed compared that of copper in order to achieve the same result.

More Stories

-

11.01.2023 | Design / Engineering

All in the Details

11.01.2023 | Design / Engineering

All in the Details

Thoughtfully engineered and driven by the details, learn more about Stackware.

-

12.01.2022 | Care / Clean

Cleaning Tutorials: The Flat-Lying Lid

12.01.2022 | Care / Clean

Cleaning Tutorials: The Flat-Lying Lid

Learn how to clean and care for The Flat-Lying Lid with this simple tutorial.

-

27.11.2021 | Use

4 Ways to Optimize Your Leftovers

27.11.2021 | Use

4 Ways to Optimize Your Leftovers

When the guests go home, one question remains: What to do with the leftovers? Stackware has the answers.

Free shipping on all North American orders.